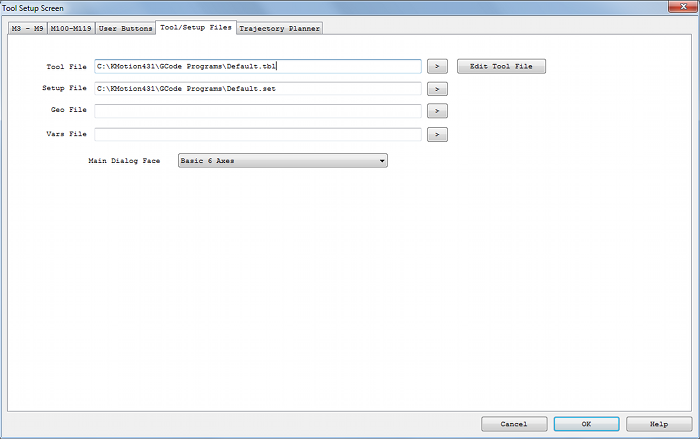

Tool Setup Screen - Files & Face

(Click on Image to Jump to related help)

The Tool Setup Screen allows KMotionCNC to be configured for a particular machine tool. Each machine tool is likely to have different motion resolution, speeds, and acceleration limits. It is also likely to different I/O requirements with regard to Spindle control and such. Additionally a machine may have different initialization and homing requirements. KMotionCNC has a flexible mechanism for defining what type of action is to be performed for various M Codes and Custom Buttons.

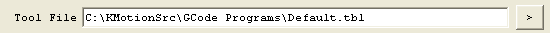

The Tool Table File specifies the disk text file which contains the table of tool definitions. In some cases the G Code Interpreter needs to know the length and diameter of the selected tool for tool path compensation. This file is used to define up to 99 tools. See also Selecting Tools.

See below for an example Tool Table POC

FMS LEN DIAM COMMENT 1

1 0.0 0.0 first tool 2

2 0.0 0.0 3

3 1.0 0.5 4

4 2.0 1.0 32

32 0.0 0.0 last tool

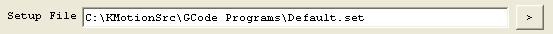

The Setup File specifies the disk text file which contains the setup table for the G Code Interpreter. In some machine tools the Interpreter may require a special initialization state. Below is the default Setup file. Modifications to the setup file should not normally be required.

Attribute

Value Other Possible Values

axis_offset_x

0.0 any real number

axis_offset_y

0.0 any real number

axis_offset_z

0.0 any real number

block_delete

ON OFF

current_x

0.0 any real number

current_y

0.0 any real number

current_z

0.0 any real number

cutter_radius_comp OFF

LEFT, RIGHT

cycle_r

0.0 any real number

cycle_z

0.0 any real number not less

than cycle_r

distance_mode

ABSOLUTE INCREMENTAL

feed_mode

PER_MINUTE INVERSE_TIME

feed_rate

5.0 any positive real number

flood

OFF ON

length_units

MILLIMETERS INCHES

mist

OFF ON

motion_mode

80

0,1,2,3,81,82,83,84,85,86,97,88,89

plane

XY YZ, ZX

slot_for_length_offset 1

any unsigned integer less than 69

slot_for_radius_comp 1

any unsigned integer less than 69

slot_in_use

1 any unsigned

integer less than 69

slot_selected

1 any unsigned

integer less than 69

speed_feed_mode

INDEPENDENT SYNCHED

spindle_speed

1000.0 any non-negative real number

spindle_turning

STOPPED CLOCKWISE, COUNTERCLOCKWISE

tool_length_offset 0.0

any non-negative real number

traverse_rate

199.0 any positive real number

![]()

Geometric correction file. Allows correcting errors in the the x,y,z positions. The callibration procedure involves moving the tool tip to an xy array of positions. For example, a precision grid might be printed on a glass or Mylar plate. By Jogging the tool tip to each row and column grid point and recording the machine's x,y,z position, a table of machine coordinates that correspond to perfect coordinates may be obtained. The "measure" button on the main KMotionCNC Screen may be used to log these positions. If such a table is specified here, the system will correct machine coordinates by bilinear xy interpolation of this table. Z is corrected for flatness at the plane of z=0 only.

The table format is shown below.

The first line specifies the number of rows and columns in the table.

The second line specifies the delta x and delta y between gridpoints.

The 3rd line defines any Table x,y offset. With an offset of 0,0 grid point row=0,col=0 will correspond to x=0, y=0. Specifying an offset will shift the table so that row=0, col=0 will correspond to the offset position. For example if the machine coordinates are such that the origin is in the middle of the range of travel, then a negative offset would be specified.

The remaining lines are row, column, x, y, z table entries.

For more information see here.

5,5

1,1

0,0

0,0,-1.767822,-2.129132,-0.331770

0,1,-0.878572,-2.068192,-0.262691

0,2,0.036983,-1.979272,-0.234576

0,3,0.930314,-1.909252,-0.237177

0,4,1.836404,-1.805593,-0.236061

1,0,-1.774018,-1.155364,-0.219091

1,1,-0.882401,-1.073801,-0.179651

1,2,0.021794,-0.987806,-0.141523

1,3,0.918408,-0.885504,-0.130446

1,4,1.792961,-0.811495,-0.124016

2,0,-1.771149,-0.166872,-0.121132

2,1,-0.883159,-0.075746,-0.074570

2,2,0.007254,0.005231,-0.051105

2,3,0.889548,0.097292,-0.035076

2,4,1.762710,0.190093,-0.016807

3,0,-1.761705,0.784817,-0.086695

3,1,-0.885633,0.869580,-0.025417

3,2,0.001747,1.008045,0.017727

3,3,0.880585,1.108997,0.059038

3,4,1.742520,1.204385,0.058162

4,0,-1.729192,1.783193,0.021364

4,1,-0.871298,1.868678,0.054451

4,2,0.005017,1.979718,0.104414

4,3,0.878944,2.104289,0.141666

4,4,1.714383,2.182679,0.144980

![]()

The Vars File is used to save all the GCode Variables which contain Fixture Offsets as well as other values. When Variables are saved to disk the file must already exist which lists which variables are to be saved. The file is read and all the variables present in the file will be replaced with their current values. Variables 5221-5226 contain the XYZABC coordinates of the first fixture offset. Skip 20 for each successive fixture.

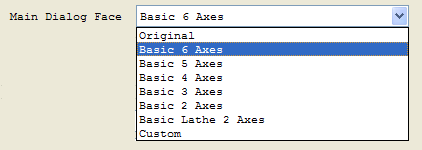

The Main Dialog Face selection selects the look of the main operation screen for KMotionCNC. Currently there are several available selections. The main difference is the number of axes, DROs and jog buttons. It is also possible to alter the dialogs by using a WindowsTM Resource Editor. Either Microsoft Visual Studio or a 3rd party freeware such as: http://www.angusj.com/resourcehacker.