KFLOP — 8-Axis Motion Controller

Click for large photo.

KFLOP is a novel motion controller that takes over the real-time requirements of your system from the host computer by buffering data and running multiple simultaneous threads deterministically. Combined with software architecture that gives you easy access to low-level functions and the ability to create your own front-end GUIs to access our libraries directly or through the .NET interface, the KFLOP motion controller is a powerful solution to your motion control needs.

In developing our KFLOP control board we wanted to offer accuracy, flexibility and capability for a reasonable price. What we achieved is a DSP-based microcontroller with 1.2 GFLOPs of processing power, a 100k Gate FPGA, 16 Mb SDRAM, 8 axes of control, lots of I/O and the ability to program in C and do path planning with G-Code for only $249. In addition, we throw in free software that has prepackaged filters and routines allowing full tuning capability for high-accuracy applications. You can begin controlling your mechanisms in minutes right out of the box.

$299 USD plus tax, S&H

In Stock

Incl. free 6' USB cable

Usually ships within 1 to 2 business days

Information on Shipping is located here

If you would like to use Bitcoin as form of payment, please send us an email to sales@dynomotion.com.

Over its lifetime, KFLOP has accumulated thousands of satisfied customers around the world who are using the KFLOP for a number of applications. In particular, the CNC community has embraced the KFLOP to run a wide variety of mills, presses, lathes, and other machining equipment.

KFLOP is easily customizable to control a variety of motor types (DC Brush Motors, Brushless Motors, Stepper Motors) as well as other physical devices. KFLOP provides low-latency, guaranteed, real-time deterministic response. Because of this, KFLOP relieves a host computer from real-time requirements (i.e. Windows is not real-time, KFLOP is).

When combined with our free software, KFLOP offers a complete motion control solution to generate Step and Direction pulses for use with 3rd Party Motor Amplifiers. Or connect up to 2 Dynomotion SnapAmps that generate current to up to 25 Amps per axis. Other applications will benefit from connecting our Kanalog I/O expansion board. Both the SnapAmp and Kanalog boards enable the use of Differential Encoders, among other things. For intense stepper motor applications, our KStep may be the perfect add-on to your KFLOP.

Check our YouTube channel to see what other users have done.

Please view our on-line documentation for full details.

Here are just a few highlights of the KFLOP:

- Real-time motion control that relieves the host computer of that duty

- High Performance 1.2 GFLOP DSP

- 64-bit Double Precision Hardware Math

- All 8 axes are sampled every 90 microseconds

- USB 2.0 Full Speed Host interface (or run stand alone)

- 16 MBytes RAM

- Digital I/O

Example Applications:

- CNC machining (build a CNC from the ground-up or retrofit with a KFLOP)

- Mills

- Lathes

- Brakepresses

- Grinders

- Spinners

- Routers

- Saws

- Robotics

- Automation

- Camera Control

- Pick-and-place

- Data Acquisition

KFLOP works with many different Input/Output devices:

- Analog Motor Amplifiers

- Step/Direction Drives

- PWM (Pulse-Width Modulated) Drives

- Relays and Switches

- Single-ended Encoders and Analog Sensors

- Amplifiers by ADVANCED Motion Control. Step/Direction works with ADVANCED Motion Control's DigiFlex® Performance™ series. KFLOP/Kanalog works well with ADVANCED Motion Control's drives that accept +/- 10V. analog and have differential encoder outputs for closed loop control. Visit ADVANCED Motion Control's 3rd Party Compatibility page and click on "Controllers".

Or refer to this Application Note (pdf)

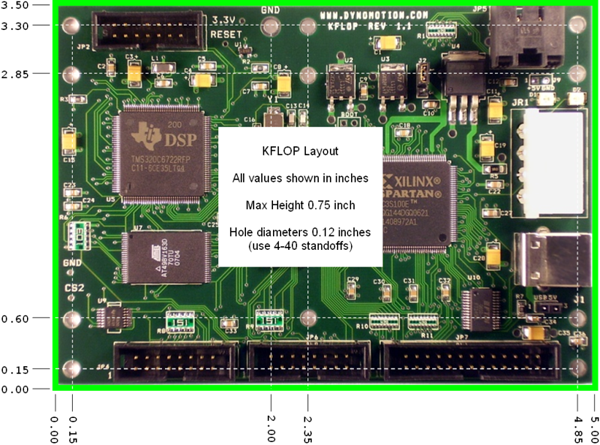

KFLOP Layout

KFLOP Block Diagram

KFLOP Hardware

| Function |

Parameter |

Specification |

| Processor |

CPU

Memory |

TMS320C67-200MHz DSP 1.2GFLOP

32/64-Bit Native Floating Point

FLASH 2 MBytes

SDRAM 16 Mbytes |

| Interface |

Host |

USB 2.0 Full Speed |

| Connectors |

I/O General Purpose

I/O Com

Aux#0 IO

Aux#1 IO

USB

System Power |

26 pin Header

8 pin RJ45

16 pin Header

16 pin Header

Type B

Molex 4-pin (Disk drive type) |

| Servo Loop |

Sample Rate

Compensation

Feed Forward |

90µs

PID + (3) IIR bi-quad Stages/Axis

Acceleration + Velocity |

| Axis |

Number

Type |

8

MicroStep / Servo / Brush / Brushless / StepDirection |

| Logic Supply |

Voltage

Max Current

Typical Current |

+5V ±10%

2.5A

0.35 A |

| User I/O |

Digital

Encoders

PWM |

46 Gen Purpose LVTTL (24 are 5V Tolerant)

(8) single-ended, 1 MHz

(8) 60KHz or prescaled by 1-256 |

| Environment |

Operating Temperature

Storage Temperature

Humidity |

0-40° C

0-40° C

20-90% Relative Humidity, non-condensing |

| Dimensions |

Length

Width

Height |

3.5 inches (89 mm)

5.0 inches (127 mm)

0.75 inches (19 mm) |

Copyright © Dynomotion, Inc.

|