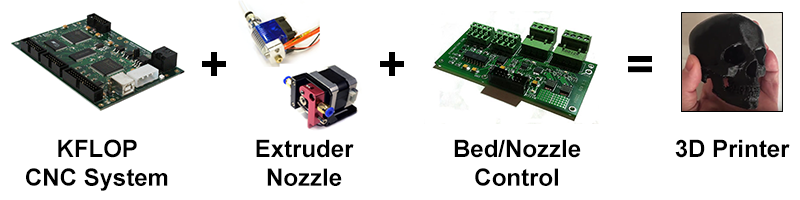

How to convert a milling machine to a 3D printer in 3 easy steps

From Dynomotion

Contents

Hardware requirements

The only real differences between a CNC machine and a 3D printer are in the tool head and the heated build platform. CNC machines use spindles, but some 3D printers use extruders (hot plastic extruder).

There are two parts in an extruder: 1) a filament drive mechanism with a stepper motor to push the filament into the hot end and 2) the hot end itself.

The temperature in the hot end must be measured and stabilized.

Extruder Nozzle

There are many third party extruders on the market. Search for popular 3D printer extruders, for example: https://reprapchampion.com/collections/extruders.

Heated Bed

A heated bed is often used to help with both the first layers to adhere to the build platform as well as to keep the part warm to reduce shrinkage and curl.

MK3 Aluminum Heater Bed (around $24).

Add a Pyrex glass to provide an absolute flat surface (around $19).

Example below shows heater bed with glass and bulldog clips.

The heater bed will connect to the KNozz board ([../KNozz.html http://www.dynomotion.com/KNozz.html]).

Bowden Extruder

Controls feeding the material into the hot end.

Metal Bowden Extruder for 1.75mm filament with stepper motor. Can be driven by KSTEP. (e.g.: All Metal V6 Hotend 1.75mm Bowden Extruder Prusa i3, around $25).

Adding a KNozz to your KFLOP

KNozz is designed to control the Nozzle Heater and Bed Heater for an Extrusion Type 3D Printer.

KNozz provides two Thermistor Inputs to allow KFLOP to monitor the temperature of both the Extruder Nozzle and Bed Heater Platform. 12-bit ADC converter provides better than 1 degree C temperature repeatability.

Learn more here:

http://www.dynomotion.com/KNozz.html

See also this related Thread on controlling with MCodes

Software requirements

CraftWare

CraftWare (https://craftunique.com/craftware) is a free and easy-to-use slicer software that converts your digital 3D object into a GCode toolpath format understood by most 3D printers.

GCode Converter Program (PostProccessExtruder)

Converts Craftware’s GCode to KMotionCNC compatible GCode (mainly changes Extruder E-words into U-words, removes some MCodes, and syntax of comments).

Link to Source Code and Executable

Video

Geppetto 3D Prints Skulls at ATX 2017 show:

https://www.youtube.com/watch?v=tOFb8tOTMlM

(Published on Feb 15, 2017)

6 Axes Cable Robot (Geppetto) controlled by Dynomotion KFLOP 3D Prints parts. Extrusion Head added to Geppetto End Effector. Demonstrates 7 axes of coordinated motion and kinematics.