simple 2 axis lathe initial lathe set up

Moderators: TomKerekes, dynomotion

- TomKerekes

- Posts: 2892

- Joined: Mon Dec 04, 2017 1:49 am

Re: simple 2 axis lathe initial lathe set up

Tool Setup | Trajectory Planner | Axis Parameters | cnts/inch have values of 0. Set to some value such as 100. Newer Version will warn you of this.

HTH

HTH

Regards,

Tom Kerekes

Dynomotion, Inc.

Tom Kerekes

Dynomotion, Inc.

Re: simple 2 axis lathe initial lathe set up

got it

my OCD does not like values to things i am not using

my OCD does not like values to things i am not using

Re: simple 2 axis lathe initial lathe set up

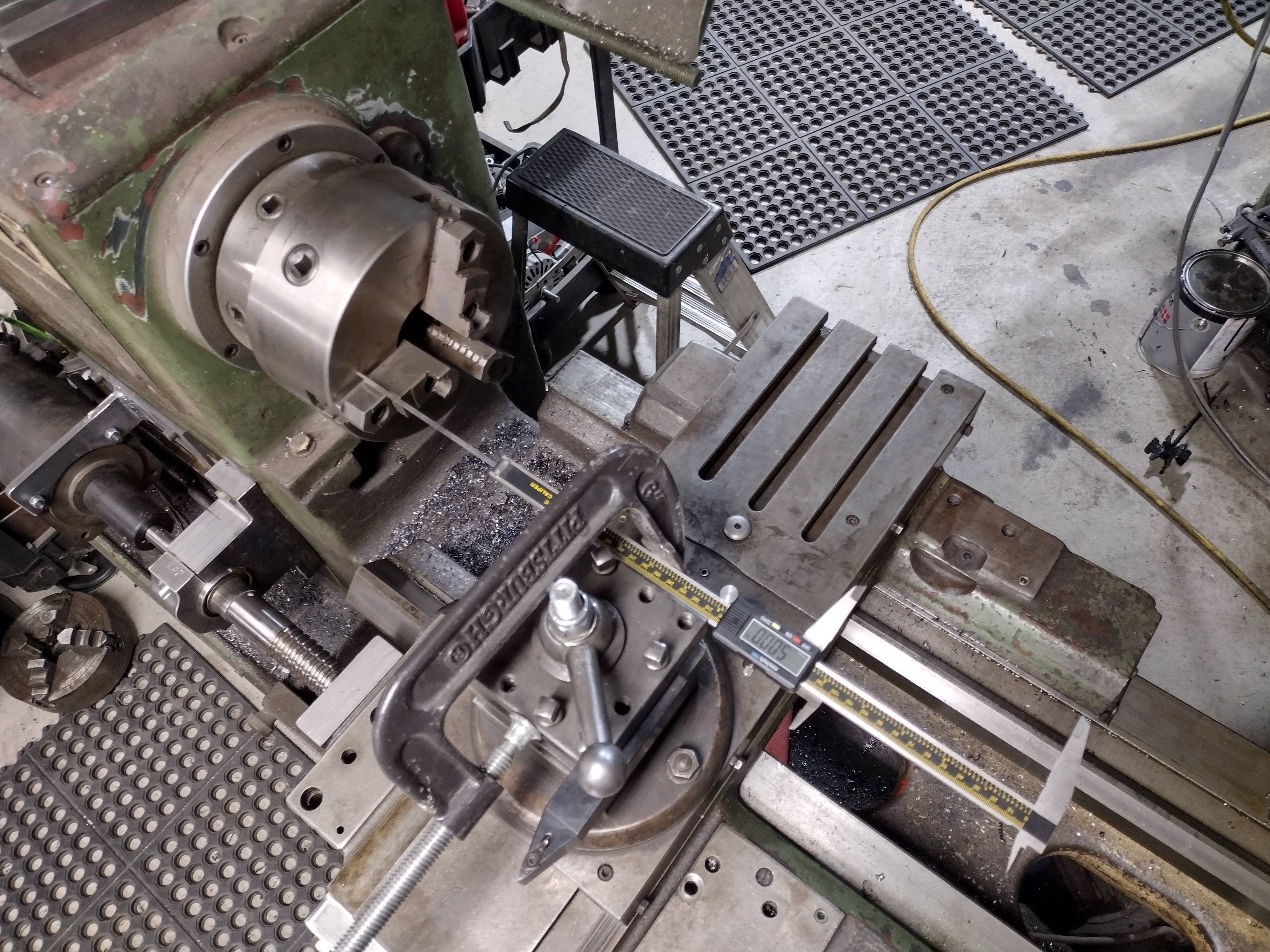

so i got my dial indicator set up on this to check the count and find that 25,500 get me about a clean .500" travel

maybe a single .001" of variance

with the 2500 count encoder this seems kinda odd on the screw pitch

is there a descent way to measure like a foot of travel?

maybe a single .001" of variance

with the 2500 count encoder this seems kinda odd on the screw pitch

is there a descent way to measure like a foot of travel?

- TomKerekes

- Posts: 2892

- Joined: Mon Dec 04, 2017 1:49 am

Re: simple 2 axis lathe initial lathe set up

I'm assuming the 25'500 figures is the counts/unit (inch in your case) setting you need to get 1/2"?

From your original/first post, if Z axis is 10mm, and encoder count is 2000, then that should give a resolution of 200counts/mm, now to get 1" travel, it should take 200*25.4, which is 5080 counts/inch.

However, that is if the count is 2000. The 2000 might mean 2000 lines, which would give 8000counts (you get 4 encoder counts per line), or 20320 counts/inch.

But then in your last post, you mention 2500, which would give figures of 6350, or 25'400 counts/inch.

25'400 is probably the magic number that you're looking for.

To check over longer distances, I've often just use the biggest digital caliper I have.

Just remember to move to the start measurement position in the same direction as you will move to do the final measurement position in order to remove as much backlash as possible from the measurements.

I.e. Start at say Z0, move to Z0.5, zero the caliper, them move Z6.5, and check if the carriage has moved 6".

From your original/first post, if Z axis is 10mm, and encoder count is 2000, then that should give a resolution of 200counts/mm, now to get 1" travel, it should take 200*25.4, which is 5080 counts/inch.

However, that is if the count is 2000. The 2000 might mean 2000 lines, which would give 8000counts (you get 4 encoder counts per line), or 20320 counts/inch.

But then in your last post, you mention 2500, which would give figures of 6350, or 25'400 counts/inch.

25'400 is probably the magic number that you're looking for.

To check over longer distances, I've often just use the biggest digital caliper I have.

Just remember to move to the start measurement position in the same direction as you will move to do the final measurement position in order to remove as much backlash as possible from the measurements.

I.e. Start at say Z0, move to Z0.5, zero the caliper, them move Z6.5, and check if the carriage has moved 6".

Re: simple 2 axis lathe initial lathe set up

sorry for the confusion.

i am getting all my parts in order of there best use

i have a 12" caliper i will try and get some reading off

thanks!

i am getting all my parts in order of there best use

i have a 12" caliper i will try and get some reading off

thanks!

Re: simple 2 axis lathe initial lathe set up

Top section looks like a Tacho, which is of no use for positioning purposes.

Re: simple 2 axis lathe initial lathe set up

thats what i was guessing

never touched one before

ill have to get an encoder on this bad boy

thanks

never touched one before

ill have to get an encoder on this bad boy

thanks