Moderators: TomKerekes, dynomotion

-

turbothis

- Posts: 331

- Joined: Fri Mar 15, 2019 4:07 pm

- Location: southern oregon

Post

by turbothis » Thu Apr 02, 2020 12:00 am

i would like to get some experience with this but cant get the G41 to work

can dynomotion do the G41 P0.1 input? or more like G41 and D1?

quick example i am getting an error on

Code: Select all

G20G17G90G94

N7S500M03

N8G00X-8.55Y-0.775Z0.5M08

N9Z0.01

N10G01Z-0.305F90.0

N11X-7.75Y-0.775F3.0

N12X-1.48Y-0.775

N13X-1.48Y-0.555

N14X-7.75Y-0.555

N15X-8.45Y-0.555

N16G00Z0.5

-

turbothis

- Posts: 331

- Joined: Fri Mar 15, 2019 4:07 pm

- Location: southern oregon

Post

by turbothis » Thu Apr 02, 2020 12:02 am

-

TomKerekes

- Posts: 2891

- Joined: Mon Dec 04, 2017 1:49 am

Post

by TomKerekes » Thu Apr 02, 2020 12:50 am

Hi Scott,

Looks like you forgot to turn off Radius Compensation with G40.

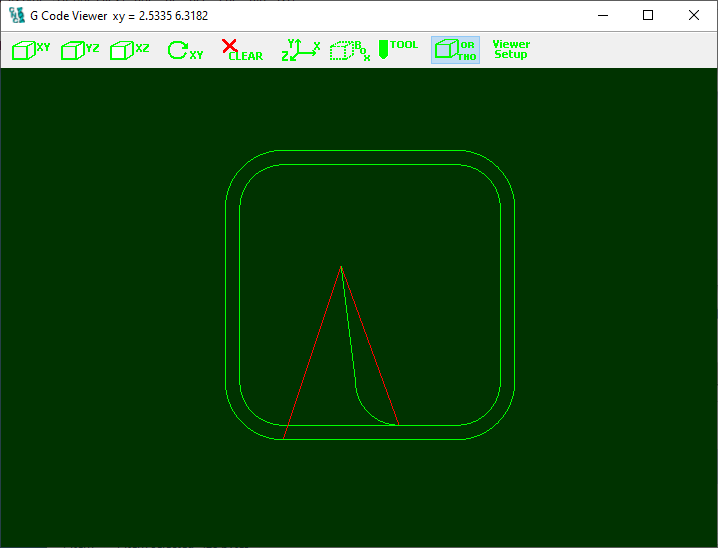

See the example: ToolRadiusInternalContour.ngc

It demos a path with and without compensation turned on.

Note you might want to select the Fanuc mode of compensation entry mode. See the

wiki.

- RComp.png (9.04 KiB) Viewed 3298 times

Regards,

Tom Kerekes

Dynomotion, Inc.

-

turbothis

- Posts: 331

- Joined: Fri Mar 15, 2019 4:07 pm

- Location: southern oregon

Post

by turbothis » Thu Apr 02, 2020 1:37 am

Thanks

i think i just learned i am screwed for cutter comp

i have an internal pocket i cut out with a key seat cutter and it just goes in a square contour

matt ( not scott)

-

turbothis

- Posts: 331

- Joined: Fri Mar 15, 2019 4:07 pm

- Location: southern oregon

Post

by turbothis » Thu Apr 02, 2020 1:38 am

Code: Select all

G20G17G40G90G94

N7S500M03

N8G00X-8.55Y-0.775Z0.5M08

N9Z0.01

N10G01Z-0.305F90.0

N11X-7.75Y-0.775F3.0

N12X-1.48Y-0.775

N13X-1.48Y-0.555

N14X-7.75Y-0.555

N15X-8.45Y-0.555

N16G00Z0.5

N17X-1.48Y-0.665

N18Z0.01

N19G01Z-0.47F10.0

N20X-1.48Y-0.555F1.0

N21X-3.255Y-0.555F4.0

N22X-3.255Y-0.775F1.0

N23X-1.48Y-0.775F4.0

N24X-1.48Y-0.665

N26Z-0.64F2.0

N27X-1.48Y-0.63F1.0

N28X-1.7866Y-0.63F3.0

N29G02X-2.0485Y-0.555I0.0J0.495

N30G01X-4.65Y-0.555

N31X-5.2Y-0.555

N32X-5.755Y-0.555

N33X-5.755Y-0.775F1.0

N34X-2.0485Y-0.775F3.0

N35G02X-1.7866Y-0.7I0.262J-0.42

N36G01X-1.48Y-0.7

N37X-1.48Y-0.665

N38Z-0.85F2.0

N39X-1.48Y-0.63F1.0

N40X-1.7866Y-0.63F3.0

N41G02X-2.0485Y-0.555I0.0J0.495

N42G01X-4.65Y-0.555

N43X-5.2Y-0.555

N44X-5.755Y-0.555

N45X-5.755Y-0.775F1.0

N46X-2.0485Y-0.775F3.0

N47G02X-1.7866Y-0.7I0.262J-0.42

N48G01X-1.48Y-0.7

N49X-1.48Y-0.665

N50Z-1.07F2.0

N51X-1.48Y-0.63F1.0

N52X-1.7866Y-0.63F3.0

N53G02X-2.0485Y-0.555I0.0J0.495

N54G01X-4.4138Y-0.555

N55G02X-4.65Y-0.615I-0.2362J0.435

N56G01X-5.2Y-0.615

N57G02X-5.4362Y-0.555I0.0J0.495

N58G01X-5.755Y-0.555

N59X-5.755Y-0.775F1.0

N60X-2.0485Y-0.775F3.0

N61G02X-1.7866Y-0.7I0.262J-0.42

N62G01X-1.48Y-0.7

N63X-1.48Y-0.665

N64Z-1.25F2.0

N65X-1.48Y-0.63F1.0

N66X-1.7866Y-0.63F3.0

N67G02X-2.0485Y-0.555I0.0J0.495

N68G01X-2.9138Y-0.555

N69G02X-3.15Y-0.615I-0.2362J0.435

N70G01X-3.6Y-0.615

N71G02X-3.8362Y-0.555I0.0J0.495

N72G01X-4.4138Y-0.555

N73G02X-4.65Y-0.615I-0.2362J0.435

N74G01X-5.2Y-0.615

N75G02X-5.4362Y-0.555I0.0J0.495

N76G01X-5.755Y-0.555

N77X-5.755Y-0.775F1.0

N78X-2.0485Y-0.775F3.0

N79G02X-1.7866Y-0.7I0.262J-0.42

N80G01X-1.48Y-0.7

N81X-1.48Y-0.665

N82Z-1.4F2.0

N83X-1.48Y-0.63F1.0

N84X-1.7866Y-0.63F3.0

N85G02X-2.0485Y-0.555I0.0J0.495

N86G01X-2.9138Y-0.555

N87G02X-3.15Y-0.615I-0.2362J0.435

N88G01X-3.6Y-0.615

N89G02X-3.8362Y-0.555I0.0J0.495

N90G01X-4.4138Y-0.555

N91G02X-4.65Y-0.615I-0.2362J0.435

N92G01X-5.2Y-0.615

N93G02X-5.4362Y-0.555I0.0J0.495

N94G01X-5.755Y-0.555

N95X-5.755Y-0.775F1.0

N96X-2.0485Y-0.775F3.0

N97G02X-1.7866Y-0.7I0.262J-0.42

N98G01X-1.48Y-0.7

N99X-1.48Y-0.665

N100G00Z0.5M09M05

X-7.0Y1.0Z1.0

N101M30

-

turbothis

- Posts: 331

- Joined: Fri Mar 15, 2019 4:07 pm

- Location: southern oregon

Post

by turbothis » Thu Apr 02, 2020 3:34 am

OK I THINK I GOT SOME WHERE TOMORROW I CAN TEST SOME CUTS!